Burning SeIC chip burning service

EBETTER COMPANY LIMITED specializes in providing IC chip programming services, including IC programming, chip programming, MCU programming, NOR Flash programming, SPI NAND programming, SD NAND programming, EEPROM programming, eMMC programming, and EPROM Our programming and other series, our programming factory covers an area of 150 square meters, with a dust-free workshop of over 100 square meters. The environment is good and the temperature and humidity are controllable. Strictly implement the management model of ISO9001. There are currently over 10 types and more than 20 sets of fully automated IC programming and testing, taping and other equipment. It can meet various packaging specifications of ics, and the monthly production capacity of the equipment can reach up to 5KK. Provide strong support for the IC programming needs of a wide range of market customers and customize programming content according to the demands of enterprises. (Programming machines: tube programming machine, tape programming machine, tray programming machine, disc turntable/turntable integrated programming machine, tape and tray integrated programming machine, etc.)

I. Definition of IC Burning

Chip burning is a method of writing program code into a chip in order to configure the chip to the required operating state. It can help users write specific program codes in the chip to achieve specific functions or optimize performance. Through burning, users can easily modify or update the program code in the chip to meet the constantly changing demands and technological developments.

Ii. Principles of IC Chip Burning

The rinciple of chip burning is to write program code in a specific programming language (such as C or assembly language), and then use a burning tool to write the program code into the chip. The program code can be in binary, hexadecimal or other form Programming Project

1.IC types: MCU/MPU, EPROM,EEPROM,FLASH,Nand Flash, PLD/CPLD,SD Card,TF Card, CF Card,eMMC Card,eMMC,MoviNand, OneNand...

2. IC encapsulation: DIP/SDIP/SOP/MSOP QSOP/SSOP/TSOP/TSSOP/PLCC/QFP/QFN/MLP/MLF/BGA/CSP/SOT/DFN...

3.IC packaging: Tray,Tube,Tape

4.Nand Flash: XTX(XT26G01CWSIGA),XTX(XTSDG01GWSIGA),HYNIX(HY27) …

5.C manufacturers: Major brands from China, the United States, Japan, Taiwan and Europe

Iv. Fully automatic Chip Programming Machine equipment

1. Automatic coiling integrated burner KA-2000

A. Equipped with SP18, it is a dedicated mass production programmer for SPI FLASH launched by Shenzhen Shuofei Technology, fully supporting high-speed mass production burning of SPI NOR FLASH, I2C/MicroWire EEPROM, etc. from various domestic and foreign manufacturers. It communicates via the USB port and does not require an external power supply.

B. t can be targeted at SOP, SSOP, TSOP, QFN, WSON, USON, etc. Wait for the chip packaging to provide a suitable burner socket. Lightweight and thin or non-standard special packages that are difficult to handle can also be customized with a burning stand.

C. It supports the feeding and discharging of tape and pallets, and can customize packaging according to the packaging requirements of customers.

D. Integrated reel and reel, with a production capacity of 2000UPH, is designed for pallet/tape chip packaging production. It features 32 workstations, four suction nozzles for high-precision picking and placing, and upper and lower CCD video alignment, capable of dotting.

2. Automatic tube-mounted burner 1213D

A. Four chips can be burned simultaneously at one time, with 12 feeding tubes and 13 discharging tubes at the same time, featuring a high degree of automation.

b. It features a fully Chinese intelligent LCD display and is equipped with double-layer tower-type light prompts, making it convenient to use.

c. Processing rate :3000 per hour, one machine can replace the workload of five people, significantly saving costs.

d. Full-process monitoring, more stable, safer, more accurate, and greatly reduces the defect rate.

e. It is equipped with the Shuofei SP328P. The SP328P is a newly launched high-speed mass production programmer dedicated to SPI FLASH by Shuofei Technology, fully supporting SPI from various domestic and foreign manufacturers

High-speed mass production burning of EEPROM such as NOR/NAND FLASH and I2C/MicroWire. Supports UID data encryption function for some chips (adding anti-copy and anti-piracy capabilities to the product), and supports offline burning and rolling code (automatic serial number) function, which can be used to generate unique serial numbers, MAC addresses, Bluetooth ids, etc. for the product...

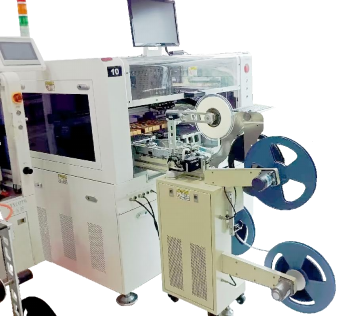

3. Tape tape burner KA42-2000

a. Capacity: 2000UPH, four burning stations, dual suction nozzles, electric feeder feeding, suitable for the burning of tape IC packaging, capable of dotting.

b. An IC automatic programming machine that realizes automatic packaging after the completion of tape winding in and out, and automatically distinguishes between OK and NG.

c. Support for offline burners. The company can install burners that support ics as needed for the ics to be programmed.

D. support IC encapsulation QFN/SOP/SSOP/TSSOP/SON/QFP... Wait for the chip packaging to provide a suitable burner socket. Lightweight and thin or non-standard special packages that are difficult to handle can also be customized with a burning stand.

e. It is equipped with the Shuofei SP328P. The SP328P is a newly launched high-speed mass production programmer dedicated to SPI FLASH by Shuofei Technology, fully supporting SPI from various domestic and foreign manufacturers

High-speed mass production burning of EEPROM such as NOR/NAND FLASH and I2C/MicroWire. Supports UID data encryption function for some chips (adding anti-copy and anti-piracy capabilities to the product), and supports offline burning and rolling code (automatic serial number) function, which can be used to generate unique serial numbers, MAC addresses, Bluetooth ids, etc. for the product...

4. Tape burner KA82-1800

a. Capacity 1800UPH, twelve burning stations, dual suction nozzles, electric feeder feeding, suitable for IC packaging burning of rolls and tapes, capable of dotting.

b. An IC automatic programming machine that realizes automatic packaging after the completion of tape winding in and out, and automatically distinguishes between OK and NG.

c. Support for offline burners. The company can install burners that support ics as needed for the ics to be programmed.

D. support IC encapsulation QFN/SOP/SSOP/TSSOP/SON/QFP... Wait for the chip packaging to provide a suitable burner socket. Lightweight and thin or non-standard special packages that are difficult to handle can also be customized with a burning stand.

e. It is equipped with the Shuofei SP328P. The SP328P is a newly launched high-speed mass production programmer dedicated to SPI FLASH by Shuofei Technology, fully supporting SPI from various domestic and foreign manufacturers

High-speed mass production burning of EEPROM such as NOR/NAND FLASH and I2C/MicroWire. Supports UID data encryption function for some chips (adding anti-copy and anti-piracy capabilities to the product), and supports offline burning and rolling code (automatic serial number) function, which can be used to generate unique serial numbers, MAC addresses, Bluetooth ids, etc. for the product...

5. Tape burner KA82-1800

a. Capacity 1800UPH, eight burning stations, dual suction nozzles, electric feeder feeding, suitable for IC packaging burning of rolls and tapes, capable of dotting.

b. An IC automatic programming machine that realizes automatic packaging after the completion of tape winding in and out, and automatically distinguishes between OK and NG.

c. Support for offline burners. The company can install burners that support ics as needed for the ics to be programmed.

D. support IC encapsulation QFN/SOP/SSOP/TSSOP/SON/QFP... Wait for the chip packaging to provide a suitable burner socket. Lightweight and thin or non-standard special packages that are difficult to handle can also be customized with a burning stand.

e. It is equipped with the Shuofei SP328P. The SP328P is a newly launched high-speed mass production programmer dedicated to SPI FLASH by Shuofei Technology, fully supporting SPI from various domestic and foreign manufacturers

High-speed mass production burning of EEPROM such as NOR/NAND FLASH and I2C/MicroWire. Supports UID data encryption function for some chips (adding anti-copy and anti-piracy capabilities to the product), and supports offline burning and rolling code (automatic serial number) function, which can be used to generate unique serial numbers, MAC addresses, Bluetooth ids, etc. for the product...

V. Chip Burning Process

1. Write program code: Use programming languages to write program code to achieve the required functions or optimize performance.

2. Compile program code: Use a compiler to compile the program code into machine code.

3. Linking executable files: Use a linker to link multiple machine code files into an executable binary file.

4. Prepare the hardware environment: Connect the programmer, burner, debugger and other hardware tools, and ensure that the interface connection with the chip is normal.

5. Burn program code: Use a burner to write executable binary files into the chip.

6. Debugging and Testing: Use a debugger to debug and test the chip to ensure that the program runs normally and achieves the required functions.

Our advantages:

First, it can meet the different types of chips of customers.

Second, block (MCU/NOR&NAND FLASH/EEPROM/I2C/block MicroWire EEPROM, etc.) and dot burn of different chip packaging, tags, and tray turn knitting/weaving turntable requirements.

Third, we have professional FAE and R&D departments.

4. Timely provision and mass production of FA burning samples for customers during the NPI stage.

V. Sign agreements with the original chip manufacturers or chip suppliers designated by the customers to provide one-stop services including chip procurement and programming.

The service process of chip burning:

-

Tel

+86 13725536313 -

Whatsapp

中文

中文